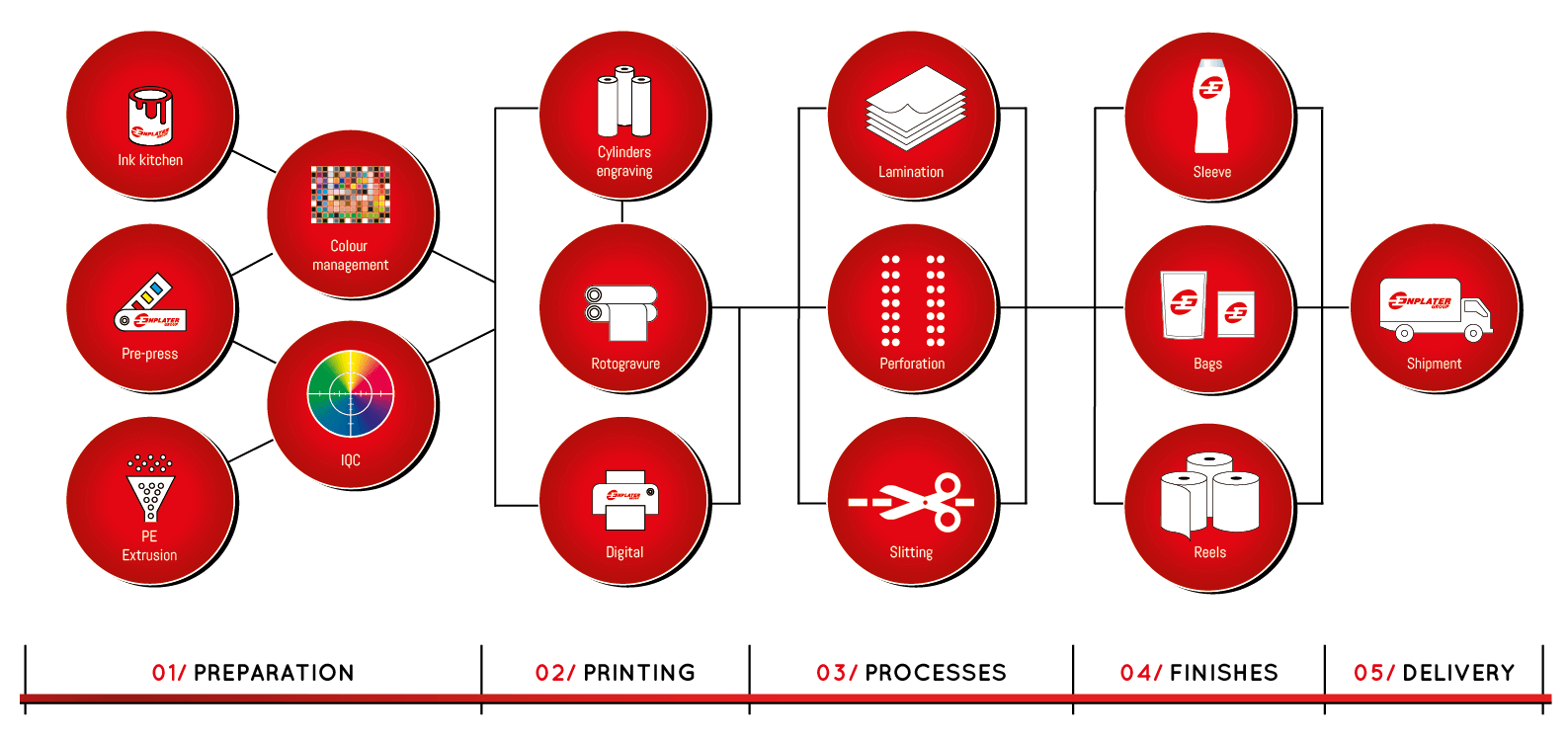

Technologies: Prepress

Direct contact between Enplater pre-press and customer designers is the key to do the right printing as fast as possible.

Enplater pre-press department has the most up to date design software to adapt the designs with the maximum guarantee.

Technologies: Colour management

Colour management is the base of the printing production process for flexible packaging, for this reason, Enplater’s team is proactive to achieve printings adjusted to the colour customer’s target.

The key to printing the right colour is the latest technology and working side by side with our customers.

Technologies: IQC

IQC technology is used by Enplater in order to control the color quality, systemizing the measurements, reports management and register.

All this information is available in every rotogravure and digital printing machine.

Technologies: Ink Kitchen

Enplater’s Ink Kitchen guarantees the fastest supply and the maximum control on inks production with all the guarantees to print the color gamut chosen by the customer.

Technologies: Extrusion

Enplater extruders produce one of the most common materials to laminate, the PE film.

Extrusion starts by feeding PE pellets from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. Enplater has different formulas depending on each specific application.

Technologies: Cylinders engraving

Cylinder engraving automatization offers the maximum agility, flexibility, and guarantee for a satisfactory result.

Technologies: Rotogravure printing

The acquisition of the most advanced printers in the market is the main pillar for Enplater competitiveness.

It assures the best printing quality on the market, even applying varnishes and cold seal.

Technologies: Digital printing

Digital printing for flexible packaging is the chance to differentiate your products on the supermarket shelf personalizing your products and do short printing runs for every specific market.

This technology afford high-quality production to create promotional campaigns, pilot tests, and new product launches.

Enplater also uses HP Mosaic combines, scales, transposes and rotates high-resolution base design patterns to create limitless unique variations. The output files can be generated in high volumes and used as variable image assets in the graphic design.

Technologies: Lamination

Enplater laminating lines offers the possibility to laminate materials solvent and solventless to guarantee the impermeability, sealability and adhesion characteristics for complex films.

Technologies: Perforation

Enplater can realize perforation and die cuts to any kind of flexible packaging using its own technology.

The laser machinery can do:

· Microperforation

· Macroperforation

· Pre-slitting

· Die cut

· Numeric sequences

Technologies: Sleeve

The sleeve is mainly applied to bottles and pots, its function is protecting, grouping, and enhancing the product with high-quality printed film completely covering and adapting its shape.

Applying materials:

· PVDC

· PETG

· OPS

· PLA

Technologies: Slitting

Enplater slitting machinery guarantees high precision slitting on any kind of flexible packaging.

Technologies: Bags

Enplater offer the possibility to produce different sizes and formats following out 365º politics to offer a full service on flexible films:

- Doypack

- 3 sides

- Maxibag

- Flat bottom side

- Flat pouch